Tag research

Enhancing survey data with high-tech, long-range drones

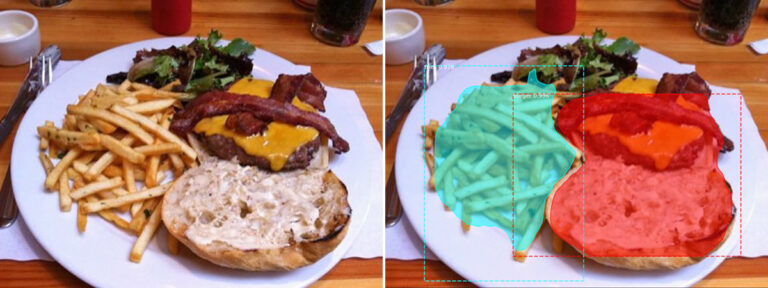

Counting carbs with AI for real-time glucose monitoring

Smart wearables that measure sweat provide continuous glucose monitoring

More than 60 per cent of incarcerated women are mothers – Listen, with Rai Reece